HYDRAULICS TO GO

HYDRAULICS TO GO

AHP Merkle not only manufactures hydraulic cylinders and electro-hydraulic linear drives, but also designs complete hydraulic systems and drives. In the course of this, we have gathered our experience and designed machine units especially for the harsh daily factory routine. They can be controlled manually as well as via the injection molding machine control system and are designed to check the functionality of push units, core pulls or even ejectors. Cylinders and limit switches are connected to the unit for this purpose. The test units can be used to perform functional tests, as well as pressure and movement tests of your hydraulic application.

THE ADVANTAGES

·THE CORE PULL UNIT BY AHP

Thanks to the simple connection to the injection molding machine, the core pull unit can also be used as a test and commissioning unit.

The connection to the injection molding machine, for example, is handled by a Hirschmann connector. This also allows the processes to be automated.

HARSH ENVIRONMENT

The new machine units by AHP Merkle were designed especially for the harsh daily factory routine.

PARAMETER MANAGEMENT

Various parameters can be set on the core pull unit, such as the switch-on and switch-off point for cooling, time delays for the respective limit switches, and many more.

EASY TO USE

The hand levers can be used to quickly and safely bleed and depressurize hydraulic components.

PRECISELY ADJUSTABLE

Precise hand levers allow sensitive operation in manual mode.

SPECIAL PURPOSE VALVES

Special purpose valves enable the system to not only be operated manually – it can also be controlled electrically.

COMPACT AND MOBILE

All machine units are very space-saving due to the compact design. The core pull unit and the test unit are mobile for easy handling.

·THE TEST UNIT BY AHP

HARSH ENVIRONMENT

The new machine units by AHP Merkle were designed especially for the harsh daily factory routine.

EXTENDABLE

The test unit can be extended from 2 circuits to 4 circuits at a later stage.

PRECISELY ADJUSTABLE

Precise hand levers allow sensitive operation in manual mode.

EASY TO USE

The hand levers can be used to quickly and safely bleed and depressurize hydraulic components.

COMPACT AND MOBILE

All machine units are very space-saving due to the compact design. The core pull unit and the test unit are mobile for easy handling.

PRESSURE AND MOVEMENT

The test unit can be used to perform both a pressure test and a movement test.

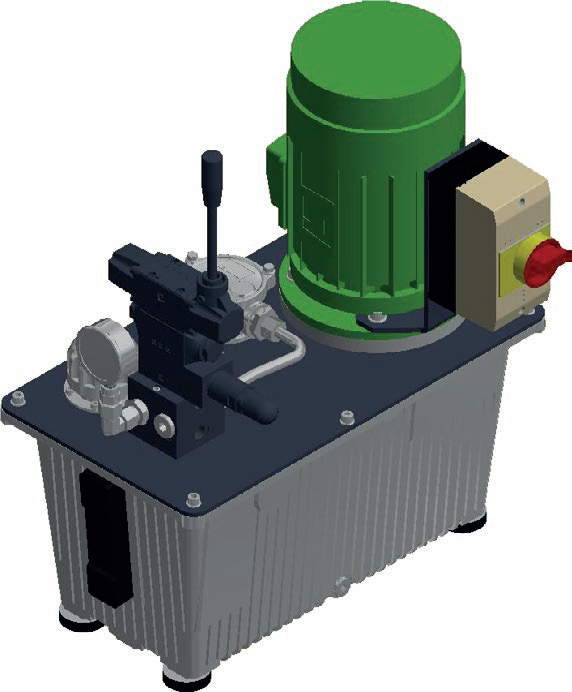

TESTING UNIT AS TABLE VERSION

THE COMPACT UNIT

This test unit is AHP's most compact version. It is used for simple functional tests of hydraulic components, but can also be used for all common functional and commissioning purposes. Despite its compact size, this unit has everything you need for everyday factory work.

• 1.5 kW drive power

• Maximum operating pressure 250 bar

• Maximum conveyed volume 3.2 l/min

• 1 circuit

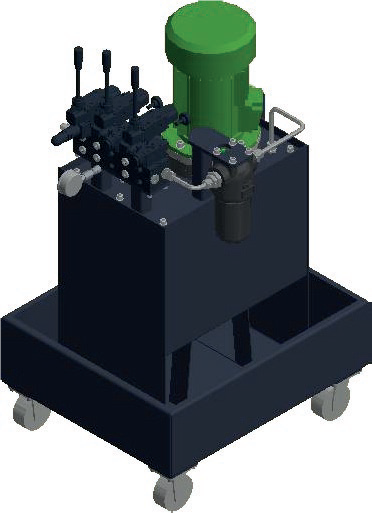

TEST UNIT

FOR TEMPORARY FUNCTIONAL TESTS OF HYDRAULIC APPLICATIONS

In addition to the core pull unit, this test unit is also equipped with high-quality PU rolls, as well as an oil collection tray. By using so-called check valves, the test objects can be under pressure! These check valves enable a pressure test to be carried out, as these valves are leak-free by design. The main advantage of this unit is the subsequent extension option from 2 circuits to 4 circuits.

• 4.0 kW drive power

• Maximum operating pressure 250 bar

• Maximum conveyed volume 8 l/min

• Up to 4 circuits

• Subsequently extendable

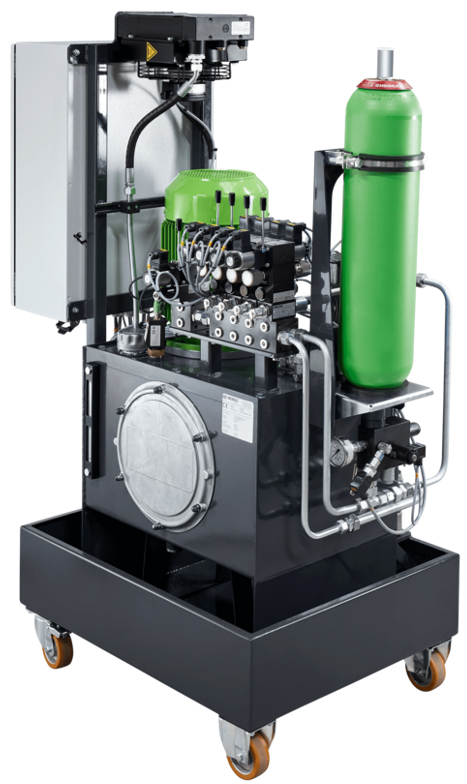

CORE PULL UNIT

THE COMPLETE SOLUTIONG AMONG THE UNITS

Various parameters can be set on the core pull unit, such as the switch-on and switch-off point for cooling, time delays for the respective limit switches, and many more. Due to the AHP special purpose valves with electric operation and hand lever operation, the drives can be very reliably controlled electrically in automatic mode. The connection to the injection molding machine, for example, is handled by a Hirschmann connector. In manual mode, the drives with a hand lever valve can be controlled very precisely and sensitively. This makes it possible to use it both as a core pull unit and as a test and commissioning unit.

• 7.5 kW and 15kW drive power

• Maximum operating pressure 250 bar

• Maximum conveyed volumes 16 l/min and 30 l/min

• Up to 8 core pulls

• The respective drives are controlled via potential-free contacts

• Mobile for easy handling

• Optional: pressure accumulator, oil-air cooler or oil-water cooler

中文

中文