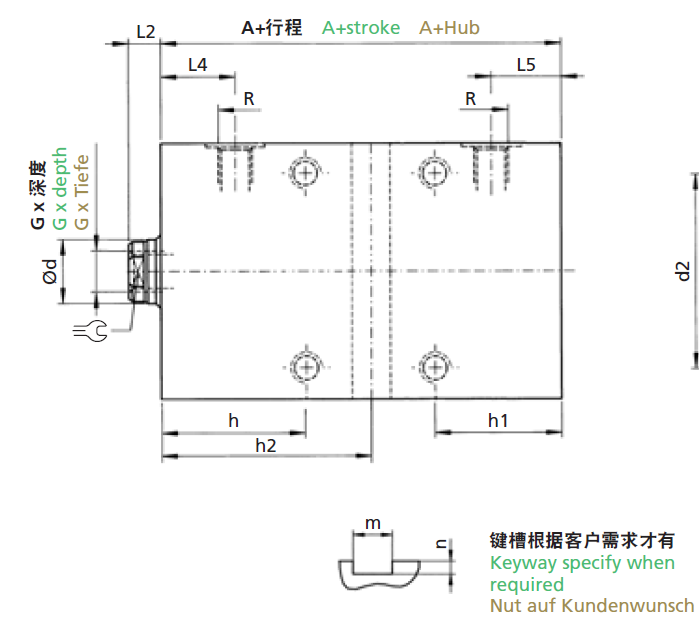

- When the stroke of the hydraulic cylinder is ≥ standard stroke h3, the standard of AHP MERKLE under the installation methods of 03, 06, 33, and 36 is 4 fixing screw holes, that is, the hole positions of the 4 mounting screw holes shown in h and h1 in the catalog; when the stroke of the hydraulic cylinder is < standard stroke h3, the standard of AHP MERKLE is 2 fixing screw holes, that is, the hole positions of the 2 mounting screw holes shown in h in the catalog; if the customer specifies that 4 fixing screw holes are required when the stroke is < standard stroke h3, please indicate “reserved” when inquiring and placing an order. h1".

- Under the installation styles of 03, 06, 33, AND 36, AHP MERKLE can process and INSTALL the keyway according to customer requirements, that is, the slot shown in h2 in the catalog. When processing and installing the keyway, the keyway value, that is, the value shown in h2, must be provided by the customer (the value of h2 has the maximum and minimum values).

Example Cylinder Style 06

.jpg)

中文

中文

.jpg)

.jpg)

.png)

.png)

.png)